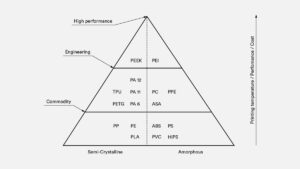

One of the key advantages of FDM (both desktop and industrial) is the technology’s wide range of materials. This includes commodity thermoplastics such as PLA and ABS, engineering materials like PA, TPU and PETG and high-performance thermoplastics, including PEEK and PEI.

Desktop FDM Machines

PLA filament is the most common material used in desktop FDM printers. Printing with PLA is relatively easy and can produce parts with finer details. When you need higher strength, ductility and thermal stability, you normally use ABS. However, ABS is more prone to warping, especially if you are using a machine that doesn’t have a heated chamber.

Another alternative for desktop FDM printing is PETG, which is comparable to ABS in its composition and how easy it is to print with. All three of these materials are suitable for most 3D printing service applications, from prototyping to form, fit and function, to low-volume production of models or functional parts.

Industrial FDM Machines

Industrial FDM machines, on the other hand, mainly use engineering thermo-plastics, including ABS, polycarbonate (PC) and Ultem. These materials usually come equipped with additives that alter their properties and make them particularly useful for industrial needs like high impact strength, thermal stability, chemical resistance and biocompatibility.

Printing in different materials will affect your part’s mechanical properties and accuracy, as well as its cost. We compare the most common FDM materials in the table below.

| Material | Characteristics |

|---|---|

| ABS | + Good strength

+ Good temperature resistance – More susceptible to warping |

| PLA | + Excellent visual quality

+ Easy to print with – Low impact strength |

| Nylon (PA) | + High strength

+ Excellent wear and chemical resistance – Low humidity resistance |

| PETG | + Food Safe*

+ Good strength + Easy to print with |

| TPU | + Very flexible

– Difficult to print accurately |

| PEI | + Excellent strength to weight

+ Excellent fire and chemical resistance – High cost |